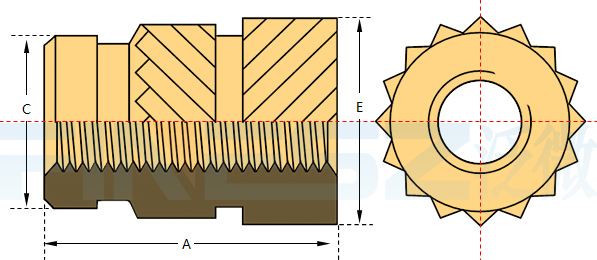

可容许较少肉厚的直孔设计

可容许较少肉厚的直孔设计 可使用热熔或超音波的方式快速装置

可使用热熔或超音波的方式快速装置 圆头导引之设计,定位效果佳;不易歪斜

圆头导引之设计,定位效果佳;不易歪斜 阶段性之外径设计,渐进式入塑胶,母材塑胶不易龟裂

阶段性之外径设计,渐进式入塑胶,母材塑胶不易龟裂 相反方向之双斜花纹设计,与塑胶紧密结合,增加扭力拉力

相反方向之双斜花纹设计,与塑胶紧密结合,增加扭力拉力

| 螺纹规格 | 型号分类 | 外径 E±0.1 |

长度(红色为推荐长度) A±0.1 |

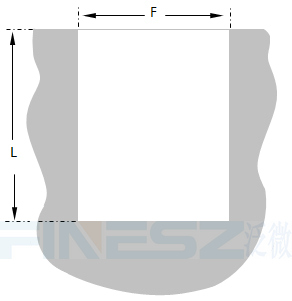

C±0.05 | 最小孔深 L |

孔径 F+0.08 |

最小 壁厚 |

|

| 铜 | 不锈钢 | |||||||

| M2*0.4 | IUTB | IUTC | 3.73 | 3,4,5 | 3.07 | A+1mm | 3.23 | 1.3 |

| M2.5*0.45 | IUTB | IUTC | 4.55 | 3,4,5,5.74 | 3.86 | A+1mm | 4.01 | 1.6 |

| M3*0.5 | IUTB | IUTC | 4.55 | 3,4,5,5.74,7,8 | 3.86 | A+1mm | 4.01 | 1.6 |

| M3.5*0.6 | IUTB | IUTC | 5.33 | 4,5,6,7.14,8 | 4.65 | A+1mm | 4.81 | 1.8 |

| M4*0.7 | IUTB | IUTC | 6.17 | 3,4,5,6,7,8.15,9,10 | 5.51 | A+1mm | 5.67 | 2.1 |

| M5*0.8 | IUTB | IUTC | 6.93 | 4,5,6,7,8,9,9.52,10 | 6.27 | A+1mm | 6.43 | 2.6 |

| M6*1.0 | IUTB | IUTC | 8.69 | 6,7,8,9,9.5,10,11,12.7,14 | 7.87 | A+1mm | 8.03 | 3.3 |

| M8*1.25 | IUTB | IUTC | 10.3 | 8,9,9.5,10,11,12.7,14 | 9.45 | A+1mm | 9.6 | 4.5 |

| M10*1.5 | IUTB | IUTC | 12.93 | 12.7,14 | 11.73 | A+1mm | 11.89 | 5.3 |

| 螺纹规格 | 型号分类 | 外径E ±.004 |

长度 A ±.004 |

C ±.004 |

最小孔深 L |

孔径F +.0003 |

最小 壁厚 |

|

| 铜 | 不锈钢 | |||||||

| #2-56 | IUTB | IUTC | .147 | .157 | .121 | .187 | .127 | .05 |

| #4-40 | IUTB | IUTC | .179 | .226 | .152 | .256 | .158 | .06 |

| #6-32 | IUTB | IUTC | .210 | .281 | .183 | .311 | .189 | .07 |

| #8-32 | IUTB | IUTC | .243 | .321 | .217 | .351 | .223 | .09 |

| #10-24 | IUTB | IUTC | .273 | .375 | .247 | .405 | .253 | .10 |

| #10-32 | IUTB | IUTC | .273 | .375 | .247 | .405 | .253 | .10 |

| 1/4-20 | IUTB | IUTC | .342 | .500 | .310 | .530 | .316 | .13 |

| 1/4-28 | IUTB | IUTC | .342 | .500 | .310 | .530 | .316 | .13 |

| 3/8-16 | IUTB | IUTC | .509 | .500 | .462 | .530 | .468 | .20 |

| 螺母规格 | 基材ABS | 基材PC | ||

| 拉出力(N) | 扭力(N·M) | 拉出力(N) | 扭力(N·M) | |

| M2.5*5.74 | 730 | 1.58 | 823 | 1.81 |

| M3*5.74 | 730 | 1.58 | 823 | 1.81 |

| M4*8.15 | 963 | 4.07 | 1690 | 5.88 |

| M5*9.52 | 1200 | 5.4 | 1710 | 7.7 |

| M6*12.7 | 2130 | 11.7 | 2660 | 14.9 |

| 螺母规格 | 基材ABS | 基材PC | ||

| 拉出力(ibs.) | 扭力(in.ibs.) | 拉出力(ibs.) | 扭力(in.ibs.) | |

| #2-56 | 57 | 4 | 112 | 8 |

| #4-40 | 165 | 14 | 185 | 16 |

| #6-32 | 197 | 25 | 295 | 31 |

| #8-32 | 216 | 36 | 365 | 52 |

| #10-32 | 269 | 54 | 380 | 80 |

| 1/4-20 | 480 | 104 | 600 | 132 |

IUT是一种代号,Insert of Ultrasonic, straight wall(可超声植入嵌件,柱形),即本页所展示的这类双斜压花螺母,生产所采用材质主要有三种:

IUT-B型:快削铜(一般为C3604);

IUT-C型:不锈钢材质(一般为SUS303易车削不锈钢);

IUT-A型:铝(7075-T6,这此类很少生产,略)

具体材料对应的化学成分如下

IUTB螺母材质:| 型号 | 牌号 | 铜(Cu) | 锌(Zn) | 铅(Pb) | 锡(Sn) | 铁(Fe) | 杂质总和 | 密度 |

| IUTB | C3604 黄铜 |

57-61 | 余量 | 1.8-3.7 | Fe+Sn≤1.2 | ≤0.5 | ≤0.3 | 8.5g/cm |

| 型号 | 牌号 | 碳(C) | 锰(Mn) | 硅(Si) | 磷(P) | 硫(S) | 镍(Ni) | 钼(Mo) | 铬(Cr) |

| IUTC | SUS303 不锈钢 |

≤0.15 | ≤2.00 | ≤1.00 | ≤0.20 | ≤0.15 | 8.00-10.00 | 可加入≤0.60 | 17.00-19.00 |